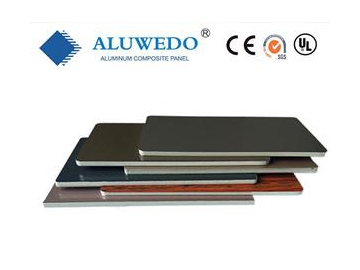

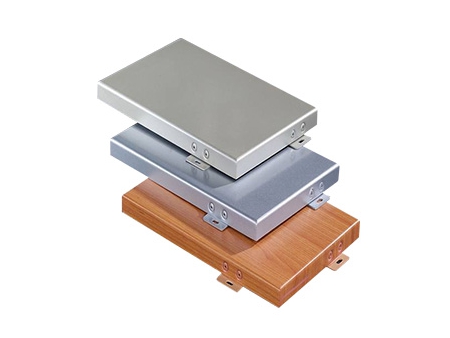

A2 Fire Resistant Aluminum Composite Panel, ACP Panel

Aluwedo® high-gloss EVE surface aluminum composite panel comes with high-quality polyurethane as the innermost coating and fluororesin as the outermost coating. It benefits from the PVDF fluorocarbon coating which features brilliant color and high gloss. This kind of panel can be used for good 10-15 years with its weather resistance performance remained as before. The diversification and uniqueness of the panel makes it unparalleled comparing with other painting systems. The ACP board is especially applicable in decorations and exhibitions for retail chains, auto 4S stores, and gas stations, and other occasions where color effects are required.

Usos

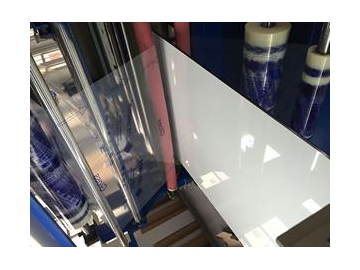

ALUWEDO high-gloss EVE Aluminum composite panel can be directly applied in silk screen printing, digital printing, spray print, and instant stick. Meanwhile, it is easy to be cut and punched. The panel is easy to be processed and fixed to all claddings, including all shapes, angles, curves, radius, bending, joint, connection, etc. It can be finished by normal machines for metal and wood.

| Features | Advantages |

| Fluoropolymer segments | outstanding weatherability, corrosion and chemical resistance, lower life cycle costs |

| Amorphous and solvent soluble | clear, wide range of gloss and color |

| Hydroxy functional | cure at ambient and elevated temperature |

| High solids/solid resins | Low VOC/reduced VOC coatings |

Advantages

1. The high-gloss EVE surface Aluminum composite panel is of extremely light weight

2. Featuring excellent flatness and high flexural strength

3. Versatile processing options using routing and folding techniques

4. A variety of panel specifications for option

5. Over 78% degree of gloss

6. Easily cleaned surface

7. Resistant to fungus, moss, decay, light and UV

8. Extremely high durability

9. Recyclable

10. EVE colours come with a 15 year external guarantee*.

Raw Material

a. High strength aluminum alloy A1100

b. LDPE core

c. Surface coating: PE coating & adhesive film from DuPont

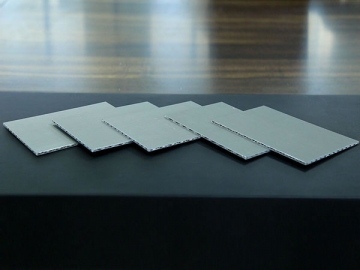

Specifications and Dimension

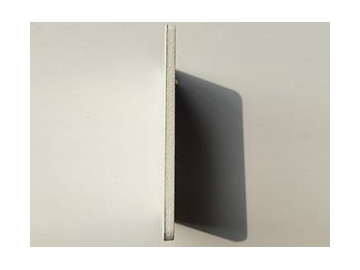

a. Thickness: 2-8mm

Recommended thickness: 3mm

b. Width: 1000-2000mm

Recommended width: 1220mm, 1250mm, 1500mm, 2000mm

c. Length: up to 5800mm or others as required

d. Aluminum thickness: 0.12~0.3mm

e. *Custom width and length is available upon request (subject to minimum quantities)

| Testing item | Standard | Result |

| Unit weight | ASTM D792 | T 3mm=4kg/m2 |

| Thermal expansion | ASTM D696 | 24-28 |

| Thermal deformation temperature | ASTM D648 | 115℃ |

| Thermal conduction | ASTM D976 | 0.102kcal/m.hr℃ |

| Flexural rigidity | ASTM D393 | 14.0*10^5 |

| Impact resistance | ASTM D732 | 1.64kgf |

| Adhesive strength | ASTM D903 | 0.77kg/mm |

| Flexural elasticity | ASTM D790 | 4030kg/mm2 |

| Shear resistance | ASTM D732 | 2.7kgf/mm2 |

| Fire propagation | ASTM E84 | qualified |

| Wind-pressure resistant | ASTM E330 | passed |

| Waterproof property | ASTM E331 | passed |

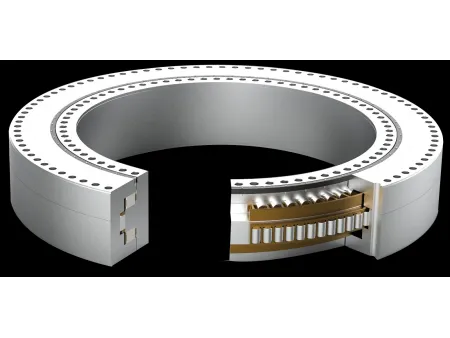

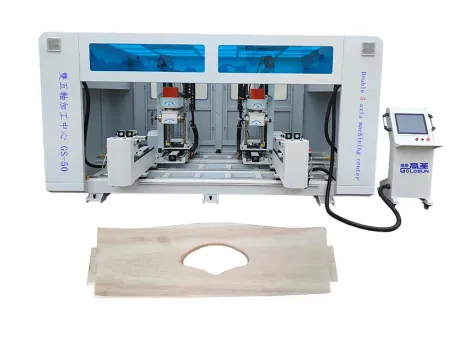

Máquina para sacar bobinas de cobre / Equipo para reciclaje de motores eléctrico / Máquina extracción cobre para motores eléctricos

motorcoil-machines.com.ar

Máquina para sacar bobinas de cobre / Equipo para reciclaje de motores eléctrico / Máquina extracción cobre para motores eléctricos

motorcoil-machines.com.ar