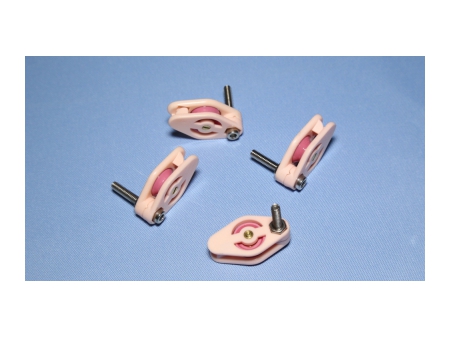

Cáncamo giratorio

- Límite de carga de trabajo 0.4-50t

- Rotación 360 grados

- Pivote 230 grados

Diseñado para la precisión y la versatilidad, este cáncamo giratorio ofrece un límite de carga de trabajo que oscila entre 0.4t y 50t. Con una rotación completa de 360 grados y un pivote de 230 grados, garantiza operaciones de elevación suaves, incluso en los ángulos más desafiantes. Su mecanismo de rodamiento de bolas permite una rotación perfecta bajo carga para una distribución uniforme de la tensión y una mayor seguridad durante la operación de elevación.

- Pasó la inspección del calibre de tapón de 6g, lo que garantiza la compatibilidad con orificios roscados de precisión

- Soportó pruebas de fatiga de carga 1.5x (20,000 ciclos) y pruebas de carga nominal 2.5x para confiabilidad

- Verificado a través de la inspección de partículas magnéticas para confirmar la integridad sin grietas

- Cumple con las normas EN1677-1, con informes de prueba certificados disponibles a pedido

- Plantas industriales: Comúnmente empleado para instalar maquinaria industrial y levantar moldes

- Transporte: Adecuado para el transporte de equipos industriales pesados como transformadores y grupos electrógenos

- Disponible en una amplia gama de tamaños, incluidos modelos personalizables de tipo tuerca (tipo tuerca 0832), para satisfacer diversas necesidades de aplicación

- El diseño de la base hexagonal garantiza una instalación segura y sin esfuerzo en la carga

- Se ofrece en M8-M150 y tamaños de rosca especiales (alargada, acortada, gruesa, fina, métrica o imperial)

- Forjado a partir de acero aleado de cromo-molibdeno de alta resistencia, templado y revenido para una resistencia y durabilidad superiores

- Recubrimiento de polvo electrostático de resina epoxi para el cuerpo del anillo; óxido negro, electroforesis o tratamientos de Dacromet para los pernos

- Cuenta con un factor de seguridad 4:1 con pruebas 100% no destructivas. Cada componente de carga está estampado con un número de lote de producción para su trazabilidad

- Dibujo de la dimensión 083

- Dibujo de la dimensión 832

(Disponible en rosca métrica y rosca UNC)

| No. de item | Límite de carga de trabajo (t) | Rosca M | Dimensiones (mm) | Par (Nm) | Peso (kg) | |||||||

| E | A±2 | B±3 | C | D | F±3 | G | K | |||||

| 0.40 | 8×1.25 | 12.0 | 30 | 43.5 | 54.0 | 12 | 97.5 | 40 | 37.0 | 10-40 | 0.44 | |

| 0.60 | 10×1.50 | 19.0 | 30 | 43.5 | 54.0 | 12 | 97.5 | 40 | 37.0 | 10-40 | 0.45 | |

| 0.70 | 12×1.75 | 19.0 | 30 | 43.5 | 54.0 | 12 | 97.5 | 40 | 37.0 | 15-40 | 0.45 | |

| 1.25 | 14×2.00 | 31.8 | 30 | 43.5 | 54.0 | 12 | 97.5 | 40 | 37.0 | 30-100 | 0.45 | |

| 1.50 | 16×2.00 | 31.8 | 30 | 43.5 | 54.0 | 12 | 97.5 | 40 | 37.0 | 45-130 | 0.48 | |

| 1.05 | 12×1.75 | 19.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 15-40 | 1.15 | |

| 1.90 | 16×2.00 | 30.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 45-130 | 1.35 | |

| 1.90 | 18×2.50 | 30.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 100-170 | 1.35 | |

| 2.00 | 20×2.50 | 30.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 100-170 | 1.40 | |

| 2.00 | 22×2.50 | 30.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 100-170 | 1.40 | |

| 3.15 | 24×3.00 | 30.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 190-280 | 1.40 | |

| 2.00 | 18×2.50 | 38.1 | 40 | 67.0 | 93.0 | 20 | 160.0 | 70 | 64.5 | 100-170 | 2.30 | |

| 2.50 | 20×2.50 | 38.1 | 40 | 67.0 | 93.0 | 20 | 160.0 | 70 | 64.5 | 100-170 | 2.30 | |

| 2.50 | 22×2.50 | 38.1 | 40 | 67.0 | 93.0 | 20 | 160.0 | 70 | 64.5 | 100-170 | 2.35 | |

| 4.00 | 24×3.00 | 38.1 | 40 | 67.0 | 93.0 | 20 | 160.0 | 70 | 64.5 | 190-280 | 2.35 | |

| 4.00 | 27×3.00 | 38.1 | 40 | 67.0 | 93.0 | 20 | 160.0 | 70 | 64.5 | 250-500 | 2.35 | |

| 5.00 | 30×3.50 | 35.0 | 40 | 67.0 | 93.0 | 20 | 160.0 | 70 | 64.5 | 270-600 | 2.50 | |

| 6.00 | 30×3.50 | 50.0 | 51 | 95.0 | 111.0 | 22 | 206.0 | 79 | 74.0 | 270-600 | 3.75 | |

| 7.50 | 33×3.50 | 50.0 | 51 | 95.0 | 111.0 | 22 | 206.0 | 79 | 74.0 | 270-600 | 3.80 | |

| 10.00 | 36×4.00 | 54.0 | 51 | 95.0 | 111.0 | 22 | 206.0 | 79 | 74.0 | 270-600 | 3.90 | |

| 10.00 | 39×4.00 | 58.0 | 51 | 95.0 | 111.0 | 22 | 206.0 | 79 | 74.0 | 350-800 | 4.00 | |

| 13.00 | 42×4.50 | 63.0 | 65 | 108.0 | 122.5 | 26 | 230.5 | 93 | 85.0 | 350-800 | 5.90 | |

| 13.00 | 45×4.50 | 68.0 | 65 | 108.0 | 122.5 | 26 | 230.5 | 93 | 85.0 | 350-800 | 6.00 | |

| 14.00 | 48×5.00 | 68.0 | 65 | 108.0 | 122.5 | 26 | 230.5 | 93 | 85.0 | 350-800 | 6.15 | |

| 20.00 | 56×5.50 | 84.0 | 70 | 120.0 | 158.0 | 32 | 278.0 | 105 | 95.0 | 350-900 | 10.00 | |

| 20.00 | 60×5.50 | 90.0 | 70 | 120.0 | 158.0 | 32 | 278.0 | 105 | 95.0 | 350-900 | 10.50 | |

| 20.0 | 64×6.0 | 95 | 70 | 120 | 158 | 32 | 278 | 105 | 95 | 500-1000 | 10.7 | |

| 25.0 | 72×6.0 | 108 | 80 | 123 | 210 | 40 | 333 | 158 | 142 | 500-1200 | 23.0 | |

| 30.0 | 80×6.0 | 120 | 80 | 123 | 210 | 40 | 333 | 158 | 142 | 500-1200 | 24.0 | |

| 35.0 | 90×6.0 | 135 | 80 | 123 | 210 | 40 | 333 | 158 | 142 | 500-1500 | 26.0 | |

| 35.0 | 100×6.0 | 135 | 80 | 123 | 210 | 40 | 333 | 158 | 142 | 500-1700 | 26.0 | |

| 31.5 | 72×6.0 | 108 | 90 | 138 | 230 | 48 | 368 | 169 | 155 | 500-1400 | 34.0 | |

| 35.0 | 80×6.0 | 120 | 90 | 138 | 230 | 48 | 368 | 169 | 155 | 500-1500 | 35.5 | |

| 40.0 | 90×6.0 | 135 | 90 | 138 | 230 | 48 | 368 | 169 | 155 | 500-1500 | 37.5 | |

| 40.0 | 100×6.0 | 135 | 90 | 138 | 230 | 48 | 368 | 169 | 155 | 500-1700 | 39.0 | |

| 50.0 | 110×6.0 | 135 | 90 | 138 | 230 | 48 | 368 | 169 | 155 | 500-1700 | 41.0 | |

| 50.0 | 120×6.0 | 135 | 90 | 138 | 230 | 48 | 368 | 169 | 155 | 500-1700 | 43.0 | |

| 50.0 | 130×6.0 | 135 | 90 | 138 | 230 | 48 | 368 | 198 | 155 | 500-1700 | 45.0 | |

| 50.0 | 140×6.0 | 135 | 90 | 138 | 230 | 48 | 368 | 198 | 155 | 500-1700 | 47.0 | |

| 50.0 | 150×6.0 | 135 | 90 | 138 | 230 | 48 | 368 | 198 | 155 | 500-1700 | 49.5 | |

* Factor de seguridad de 4:1;

* La longitud y la rosca de los pernos se pueden hacer de acuerdo con los requisitos;

* La 'B' representa la estructura grande, la 'S' representa la estructura pequeña;

Aplicaciones de carga de trabajo

| Método de elevación | |||||||||||

| Número de ramales de eslingas | 1 | 1 | 1 | 1 | 2 | 2 | 3-4 | 3-4 | |||

| Ángulo de elevación | 0° | 0° | 90° | 90° | 0-45° | 45-60° | Asimetría | 0-45° | 45-60° | Asimetría | |

| No. de item | Rosca M | Límite de carga de trabajo (t) | |||||||||

| BLT083-M8 | 8 | 0.6 | 1.2 | 0.40 | 0.8 | 0.6 | 0.4 | 0.4 | 0.8 | 0.6 | 0.4 |

| BLT083-M10 | 10 | 0.9 | 1.8 | 0.60 | 1.2 | 0.8 | 0.6 | 0.6 | 1.3 | 0.9 | 0.6 |

| BLT083-M12S | 12 | 1.2 | 2.4 | 0.70 | 1.4 | 1.0 | 0.7 | 0.7 | 1.5 | 1.1 | 0.7 |

| BLT083-M14 | 14 | 2.0 | 4.0 | 1.25 | 2.5 | 1.8 | 1.3 | 1.3 | 2.6 | 1.9 | 13 |

| BLT083-M16S | 16 | 2.6 | 5.2 | 1.50 | 3.0 | 2.1 | 1.5 | 1.5 | 3.2 | 2.3 | 1.5 |

| BLT083-M12B | 12 | 1.6 | 3.2 | 1.05 | 2.1 | 1.5 | 1.1 | 1.1 | 2.2 | 1.6 | 1.1 |

| BLT083-M16B | 16 | 3.0 | 6.0 | 1.90 | 3.8 | 2.7 | 1.9 | 1.9 | 4.0 | 2.9 | 1.9 |

| BLT083-M18S | 18 | 3.0 | 6.0 | 1.90 | 3.8 | 2.7 | 1.9 | 1.9 | 4.0 | 2.9 | 1.9 |

| BLT083-M20S | 20 | 3.5 | 7.0 | 2.00 | 4.0 | 2.8 | 2.0 | 2.0 | 4.2 | 3.0 | 2.0 |

| BLT083-M22S | 22 | 3.5 | 7.0 | 2.00 | 4.0 | 2.8 | 2.0 | 2.0 | 4.2 | 3.0 | 2.0 |

| BLT083-M24S | 24 | 5.0 | 10.0 | 3.15 | 6.3 | 4.4 | 3.2 | 3.2 | 6.6 | 4.7 | 3.2 |

| BLT083-M18B | 18 | 3.6 | 7.2 | 2.00 | 4.0 | 2.8 | 2.0 | 2.0 | 4.2 | 3.0 | 2.0 |

| BLT083-M20B | 20 | 4.0 | 8.0 | 2.50 | 5.0 | 3.5 | 2.5 | 2.5 | 5.3 | 3.8 | 2.5 |

| BLT083-M22B | 22 | 4.0 | 8.0 | 2.50 | 5.0 | 3.5 | 2.5 | 2.5 | 5.3 | 3.8 | 2.5 |

| BLT083-M24B | 24 | 7.0 | 14.0 | 4.00 | 8.0 | 5.6 | 4.0 | 4.0 | 8.4 | 6.0 | 4.0 |

| BLT083-M27 | 27 | 7.0 | 14.0 | 4.00 | 8.0 | 5.6 | 4.0 | 4.0 | 8.4 | 6.0 | 4.0 |

| BLT083-M30S | 30 | 7.0 | 14.0 | 5.00 | 10.0 | 7.0 | 5.0 | 5.0 | 10.5 | 7.5 | 5.0 |

| BLT083-M30B | 30 | 10.0 | 20.0 | 6.00 | 12.0 | 84 | 6.0 | 6.0 | 12.6 | 9.0 | 6.0 |

| BLT083-M33 | 33 | 15.0 | 30.0 | 7.50 | 15.0 | 10.5 | 7.5 | 7.5 | 15.8 | 11.3 | 7.5 |

| BLT083-M36 | 36 | 15.0 | 30.0 | 10.00 | 20.0 | 14.0 | 10.0 | 10.0 | 21.0 | 15.0 | 10.0 |

| BLT083-M39 | 39 | 15.0 | 30.0 | 10.00 | 20.0 | 14.0 | 10.0 | 10.0 | 21.0 | 15.0 | 10.0 |

| BLT083-M42 | 42 | 17.0 | 34.0 | 13.00 | 26.0 | 18.2 | 13.0 | 13.0 | 27.3 | 19.5 | 13.0 |

| BLT083-M45 | 45 | 17.0 | 34.0 | 13.00 | 26.0 | 18.2 | 13.0 | 13.0 | 27.3 | 19.5 | 13.0 |

| BLT083-M48 | 48 | 18.0 | 36.0 | 14.00 | 28.0 | 19.6 | 14.0 | 14.0 | 29.4 | 21.0 | 14.0 |

| BLT083-M56 | 56 | 28.0 | 56.0 | 20.00 | 40.0 | 28.0 | 20.0 | 20.0 | 42.0 | 30.0 | 20.0 |

| BLT083-M60 | 60 | 28.0 | 56.0 | 20.00 | 40.0 | 28.0 | 20.0 | 20.0 | 42.0 | 30.0 | 20.0 |

| BLT083-M64 | 64 | 28.0 | 56 | 20.0 | 40 | 28.0 | 20.0 | 20.0 | 42.0 | 30.0 | 20.0 |

| BLT083-M72-S | 72 | 31.5 | 63 | 25.0 | 50 | 35.0 | 25.0 | 25.0 | 52.5 | 37.5 | 25.0 |

| BLT083-M80-S | 80 | 38.0 | 76 | 30.0 | 60 | 42.0 | 30.0 | 30.0 | 63.0 | 45.0 | 30.0 |

| BLT083-M90-S | 90 | 40.0 | 80 | 35.0 | 70 | 49.0 | 35.0 | 35.0 | 73.5 | 52.5 | 35.0 |

| BLT083-M100-S | 100 | 40.0 | 80 | 35.0 | 70 | 49.0 | 35.0 | 35.0 | 73.5 | 52.5 | 35.0 |

| BLT083-M72-B | 72 | 40.0 | 80 | 31.5 | 63 | 44.1 | 31.5 | 31.5 | 66.2 | 47.3 | 31.5 |

| BLT083-M80-B | 80 | 40.0 | 80 | 35.0 | 70 | 49.0 | 35.0 | 35.0 | 73.5 | 52.5 | 35.0 |

| BLT083-M90-B | 90 | 50.0 | 100 | 40.0 | 80 | 56.0 | 40.0 | 40.0 | 84.0 | 60.0 | 40.0 |

| BLT083-M100-B | 100 | 50.0 | 100 | 40.0 | 80 | 56.0 | 40.0 | 40.0 | 84.0 | 60.0 | 40.0 |

| BLT083-M110 | 110 | 50.0 | 100 | 50.0 | 100 | 70.0 | 50.0 | 50.0 | 105.0 | 75.0 | 50.0 |

| BLT083-M120 | 120 | 50.0 | 100 | 50.0 | 100 | 70.0 | 50.0 | 50.0 | 105.0 | 75.0 | 50.0 |

| BLT083-M130 | 130 | 50.0 | 100 | 50.0 | 100 | 70.0 | 50.0 | 50.0 | 105.0 | 75.0 | 50.0 |

| BLT083-M140 | 140 | 50.0 | 100 | 50.0 | 100 | 70.0 | 50.0 | 50.0 | 105.0 | 75.0 | 50.0 |

| BLT083-M150 | 150 | 50.0 | 100 | 50.0 | 100 | 70.0 | 50.0 | 50.0 | 105.0 | 75.0 | 50.0 |

| No. de item | Límite de carga de trabajo (t) | Rosca | Dimensiones (mm) | Par (Nm) | Peso (kg) | ||||||||

| M | TPI | E | A±2 | B±3 | C | D | F±3 | G | K | ||||

| 0.60 | 3/8 | 16.0 | 19.0 | 30 | 43.5 | 54.0 | 12 | 97.5 | 40 | 37.0 | 10-40 | 0.50 | |

| 0.70 | 1/2 | 13.0 | 19.0 | 30 | 43.5 | 54.0 | 12 | 97.5 | 40 | 37.0 | 15-40 | 0.50 | |

| 1.50 | 5/8 | 11.0 | 31.8 | 30 | 43.5 | 54.0 | 12 | 97.5 | 40 | 37.0 | 45-130 | 0.50 | |

| 1.05 | 1/2 | 13.0 | 19.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 15-40 | 1.15 | |

| 1.90 | 5/8 | 11.0 | 30.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 45-130 | 1.35 | |

| 1.90 | 3/4 | 10.0 | 30.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 45-130 | 1.40 | |

| 2.00 | 7/8 | 9.0 | 30.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 100-170 | 1.40 | |

| 3.15 | 1 | 8.0 | 30.0 | 34 | 54.5 | 78.0 | 16 | 132.5 | 59 | 54.5 | 190-280 | 1.40 | |

| 2.00 | 3/4 | 10.0 | 38.1 | 40 | 67.0 | 93.0 | 20 | 160.0 | 70 | 64.5 | 45-130 | 2.50 | |

| 2.50 | 7/8 | 9.0 | 38.1 | 40 | 67.0 | 93.0 | 20 | 160.0 | 70 | 64.5 | 100-170 | 2.50 | |

| 4.00 | 1 | 8.0 | 38.1 | 40 | 67.0 | 93.0 | 20 | 160.0 | 70 | 64.5 | 190-280 | 2.50 | |

| 6.00 | 1-1/4 | 7.0 | 50.0 | 51 | 95.0 | 111.0 | 22 | 206.0 | 79 | 74.0 | 270-600 | 4.00 | |

| 10.00 | 1-1/2 | 6.0 | 54.0 | 51 | 95.0 | 111.0 | 22 | 206.0 | 79 | 74.0 | 270-600 | 4.00 | |

| 13.00 | 1-3/4 | 5.0 | 68.0 | 65 | 108.0 | 122.5 | 26 | 230.5 | 93 | 85.0 | 350-800 | 6.00 | |

| 14.00 | 2 | 4.5 | 68.0 | 65 | 108.0 | 122.5 | 26 | 230.5 | 93 | 85.0 | 350-800 | 6.30 | |

| 17.00 | 2 | 4.5 | 84.0 | 70 | 120.0 | 158.0 | 32 | 278.0 | 105 | 95.0 | 350-800 | 11.00 | |

| 20.00 | 2-1/4 | 4.5 | 84.0 | 70 | 120.0 | 158.0 | 32 | 278.0 | 105 | 95.0 | 350-900 | 11.00 | |

| 20.00 | 2-1/2 | 4.0 | 95.0 | 70 | 120.0 | 158.0 | 32 | 278.0 | 105 | 95.0 | 350-900 | 11.00 | |

| 25.00 | 3 | 4.0 | 108.0 | 80 | 123.0 | 210.0 | 40 | 333.0 | 158 | 142.0 | 500-1400 | 23.00 | |

* Factor de seguridad de 4:1;

* La longitud y la rosca de los pernos se pueden hacer de acuerdo con los requisitos;

Aplicaciones de carga de trabajo

| Método de elevación | |||||||||||

| Número de ramales de eslingas | 1 | 2 | 2 | 2 | 2 | 3-4 | 3-4 | ||||

| Ángulo de elevación | 0° | 0° | 90° | 90° | 0-45° | 45-60° | Asimetría | 0-45° | 45-60° | Asimetría | |

| No. de item | Rosca M | Límite de carga de trabajo (t) | |||||||||

| BLT083-3/8 | 3/8 | 0.9 | 1.8 | 0.60 | 1.2 | 0.8 | 0.6 | 0.6 | 1.3 | 0.9 | 0.6 |

| BLT083-1/2S | 1/2 | 1.2 | 2.4 | 0.70 | 1.4 | 1.0 | 0.7 | 0.7 | 1.5 | 1.1 | 0.7 |

| BLT083-5/8S | 5/8 | 2.6 | 5.2 | 1.50 | 3.0 | 2.1 | 1.5 | 1.5 | 3.2 | 2.3 | 1.5 |

| BLT083-1/2B | 1/2 | 1.6 | 3.2 | 1.05 | 2.1 | 1.5 | 1.1 | 1.1 | 2.2 | 1.6 | 1.1 |

| BLT083-5/8B | 5/8 | 3.0 | 6.0 | 1.90 | 3.8 | 2.7 | 1.9 | 1.9 | 4.0 | 2.9 | 1.9 |

| BLT083-3/4S | 3/4 | 3.0 | 6.0 | 1.90 | 3.8 | 2.7 | 1.9 | 1.9 | 4.0 | 2.9 | 1.9 |

| BLT083-7/8S | 7/8 | 3.5 | 7.0 | 2.00 | 4.0 | 2.8 | 2.0 | 2.0 | 4.2 | 3.0 | 2.0 |

| BLT083-15 | 1 | 5.0 | 10.0 | 3.15 | 6.3 | 4.4 | 3.2 | 3.2 | 6.6 | 4.7 | 3.2 |

| BLT083-3/4B | 3/4 | 3.6 | 7.2 | 2.00 | 4.0 | 2.8 | 2.0 | 2.0 | 4.2 | 3.0 | 2.0 |

| BLT083-7/8B | 7/8 | 4.0 | 8.0 | 2.50 | 5.0 | 3.5 | 2.5 | 2.5 | 5.3 | 3.8 | 2.5 |

| BLT083-1B | 1 | 7.0 | 14.0 | 4.00 | 8.0 | 5.6 | 4.0 | 4.0 | 8.4 | 6.0 | 4.0 |

| BLT083-1-1/4 | 1-1/4 | 10.0 | 20.0 | 6.00 | 12.0 | 8.4 | 6.0 | 6.0 | 12.6 | 9.0 | 6.0 |

| BLT083-1-1/2 | 1-1/2 | 15.0 | 30.0 | 10.00 | 20.0 | 14.0 | 10.0 | 10.0 | 21.0 | 15.0 | 10.0 |

| BLT083-1-3/4 | 1-3/4 | 17.0 | 34.0 | 13.00 | 26.0 | 18.2 | 13.0 | 13.0 | 27.3 | 19.5 | 13.0 |

| BLT083-2S | 2 | 18.0 | 36.0 | 14.00 | 28.0 | 19.6 | 14.0 | 14.0 | 29.4 | 21.0 | 14.0 |

| BLT083-2B | 2 | 25.0 | 50.0 | 17.00 | 34.0 | 23.8 | 17.0 | 17.0 | 35.7 | 25.5 | 17.0 |

| BLT083-2-1/4 | 2-1/4 | 25.0 | 50.0 | 20.00 | 40.0 | 28.0 | 20.0 | 20.0 | 42.0 | 30.0 | 20.0 |

| BLT083-2-1/2 | 2-1/2 | 28.0 | 56.0 | 20.00 | 40.0 | 28.0 | 20.0 | 20.0 | 42.0 | 30.0 | 20.0 |

| BLT083-3S | 3 | 31.5 | 63.0 | 25.00 | 50.0 | 35.0 | 25.0 | 25.0 | 52.5 | 37.5 | 25.0 |

| No. de item | Límite de carga de trabajo (t) | Rosca M | Dimensiones (mm) | Peso (kg) | |||||||

| E | A±2 | B±3 | C | D | F±3 | G | K | ||||

| 0.40 | 8×1.25 | 15 | 30 | 43.5 | 76.0 | 12 | 119.5 | 40 | 37.0 | 0.6 | |

| 0.60 | 10×1.50 | 15 | 30 | 43.5 | 76.0 | 12 | 119.5 | 40 | 37.0 | 0.6 | |

| 0.70 | 12×1.75 | 15 | 30 | 43.5 | 76.0 | 12 | 119.5 | 40 | 37.0 | 0.6 | |

| 1.25 | 14×2.00 | 20 | 30 | 43.5 | 82.0 | 12 | 125.5 | 40 | 37.0 | 0.6 | |

| 1.50 | 16×2.00 | 20 | 30 | 43.5 | 82.0 | 12 | 125.5 | 40 | 37.0 | 0.6 | |

| 2.00 | 18×2.50 | 25 | 40 | 67.0 | 128.0 | 20 | 195.0 | 70 | 64.5 | 3.2 | |

| 2.50 | 20×2.50 | 25 | 40 | 67.0 | 128.0 | 20 | 195.0 | 70 | 64.5 | 3.2 | |

| 2.50 | 22×2.50 | 25 | 40 | 67.0 | 128.0 | 20 | 195.0 | 70 | 64.5 | 3.2 | |

| 4.00 | 24×3.00 | 30 | 40 | 67.0 | 128.0 | 20 | 195.0 | 70 | 64.5 | 3.2 | |

| 6.00 | 30×3.50 | 40 | 51 | 95.0 | 164.0 | 22 | 259.0 | 79 | 74.0 | 5.3 | |

| 7.50 | 33×3.50 | 40 | 51 | 95.0 | 164.0 | 22 | 259.0 | 79 | 74.0 | 5.3 | |

| 10.00 | 36×4.00 | 45 | 51 | 95.0 | 164.0 | 22 | 259.0 | 79 | 74.0 | 5.3 | |

| 10.00 | 39×4.00 | 45 | 51 | 95.0 | 164.0 | 22 | 259.0 | 79 | 74.0 | 5.3 | |

| 13.00 | 42×4.50 | 63 | 65 | 108.0 | 190.5 | 26 | 298.5 | 93 | 85.0 | 8.7 | |

| 13.00 | 45×4.50 | 68 | 65 | 108.0 | 198.5 | 26 | 306.5 | 93 | 85.0 | 8.7 | |

| 14.00 | 48×5.00 | 68 | 65 | 108.0 | 198.5 | 26 | 306.5 | 93 | 85.0 | 8.7 | |

| 20.00 | 56×5.50 | 84 | 70 | 120.0 | 254.0 | 32 | 374.0 | 105 | 95.0 | 14.0 | |

| 20.00 | 60×5.50 | 90 | 70 | 120.0 | 261.0 | 32 | 381.0 | 105 | 95.0 | 14.0 | |

| 20.00 | 64×6.00 | 95 | 70 | 120.0 | 267.0 | 32 | 387.0 | 105 | 95.0 | 14.0 | |

| 31.50 | 72×6.00 | 108 | 90 | 138.0 | 347.0 | 48 | 485.0 | 169 | 155.0 | 47.0 | |

| 35.00 | 80×6.00 | 120 | 90 | 138.0 | 352.0 | 48 | 490.0 | 169 | 155.0 | 48.0 | |

| 40.00 | 90×6.00 | 135 | 90 | 138.0 | 388.0 | 48 | 526.0 | 169 | 155.0 | 51.0 | |

| 40.00 | 100×6.00 | 135 | 90 | 138.0 | 388.0 | 48 | 526.0 | 169 | 155.0 | 50.0 | |

* Factor de seguridad de 4:1;

* La longitud y la rosca de los pernos se pueden hacer de acuerdo con los requisitos;