Paper Pulping Machine (Hydrapulper D-Type)

Pulper desintegrador de pasta de papel (Hidro-desintegrador Tipo D)

Nuestro Pulper desintegrador de papel está disiñado con placa de tamizador tipoD de modo que puede evitar el bloqueo del orificio del equipo de tamizador.Dado que éste Pulper desintegrador de pasta de papel tiene las ventajas de granfuerza de recorrido, alta velocidad y fuerte capacidad de producción, esampliamente usada en el reciclaje de papel residual y en las industrias defabricación de papel. Con una calidad confiable y precio razonable, nuestroequipo pulper desintegrador de pasta de papel es preferido por muchos clientesde varios paises tales como Arabia Saudita, Ecuador, Indonesia, entre otros.

Aplicación

Nuestra Pulper desintegrador de pasta de papeles apto para la fabricación de manera intermitente o continua de OCC ydesperdicios de papel. Cuenta con una salida especial para impurezas pesadascon el fin de proteger la máquina del daño que pueden provocar metales pesadosdurante el proceso de descarga de residuos.

Estructura

Gracias a la tinaja en forma de D de la máquina, la manera en que se genera elvórtice en el pulper convencional ha cambiado. El vórtice se intensifica paraque la paca de papel puede ser rápidamente empapada en le líquido. De estemodo, diminuye el tiempo de fabricación de la pasta y la capacidad deproducción de la máquina puede ser mejorado.

Especificaciones delPulper desintegrador de pasta de papel (Hidro-desintegrador Tipo D)

| Modelo | Capacidad (t/24h) | volumen Efectivo (m3) | Diámetro del Rotor (mm) | tipo de Rotor | Consistencia del material (%) | Tamaño del agujero del tamiz (mm) | potencia del Motor (KW) |

| ZDS80 | 60~70 | 10 | Ф850 | P.S.Vokes | 3~5 | Ф10~24 | 132 |

| ZDS81 | 100~120 | 15 | Ф1000 | 3~5 | Ф10~24 | 160 | |

| ZDS82 | 130~170 | 20 | Ф1150 | 3~5 | Ф10~24 | 200 | |

| ZDS83 | 180~220 | 25 | Ф1300 | 3~5 | Ф10~24 | 250 | |

| ZDS84 | 230~270 | 30 | Ф1500 | 3~5 | Ф10~24 | 280 | |

| ZDS | 270~300 | 35 | Ф1700 | 3~5 | Ф10~24 | 315 | |

| ZDS85 | 300~350 | 40 | Ф1700 | 3~5 | Ф10~24 | 355 | |

| ZDS86 | 360~420 | 50 | Ф1950 | 3~5 | Ф10~24 | 400 | |

| ZDS86(J) | 360~420 | 50 | Ф1950 | 3~5 | Ф10~24 | 450 | |

| ZDS87(J) | 430~500 | 60 | Ф2150 | 3~5 | Ф10~24 | 560 | |

| ZDS88(J) | 530~580 | 70 | Ф2350 | 3~5 | Ф10~24 | 630 | |

| ZDS89(J) | 600~660 | 80 | Ф2550 | 3~5 | Ф10~24 | 710 | |

| ZDS90(J) | 680~730 | 90 | Ф2750 | 3~5 | Ф10~24 | 800 | |

| ZDS91(J) | 750~800 | 100 | Ф2950 | 3~5 | Ф10~24 | 900 | |

| ZDS92(J) | 830~880 | 110 | Ф3150 | 3~5 | Ф10~24 | 1000 | |

| ZDS93(J) | 900~950 | 120 | Ф3350 | 3~5 | Ф10~24 | 1120 |

PaperPulping Machine (Hydrapulper D-Type)

Paper Pulping Machine (Hydrapulper D-Type)

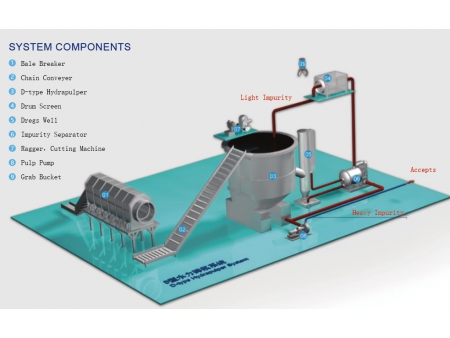

Our paper pulping machine is designed with D type screen plate so that it canavoid the blockingof screen hole. As this paper pulping machine has the advantages of largestroke force, fast speed and strong production capacity, it is widely used inwaste paper recycling and papermaking industries. With reliable quality andreasonable price, our paper pulping equipment is favored by customers from manycountries such as Saudi Arabia ,Ecuador , Indonesia ,among others.

Our paper pulping machine is suitable for theintermittent or continuous pulping of OCC and wastepaper. There is a special outlet for heavy impurities so that the machine maynot be damaged by heavy metals during the process of discharging waste.

Structure

Thanks to the machine’s D-shapedvat, the way of generating vortex in the conventional pulper has been changed.The vortex is intensified so that the paper bale can be quickly soaked into theliquid. In thisway, the pulping time is decreased and the production capability of the pulpingmachine can be improved.

Specifications of PaperPulping Machine (HydrapulperD-Type)

Our paper pulping machine is designed with D type screen plate so that it canavoid the blockingof screen hole. As this paper pulping machine has the advantages of largestroke force, fast speed and strong production capacity, it is widely used inwaste paper recycling and papermaking industries. With reliable quality andreasonable price, our paper pulping equipment is favored by customers from manycountries such as

Our paper pulping machine is suitable for theintermittent or continuous pulping of OCC and wastepaper. There is a special outlet for heavy impurities so that the machine maynot be damaged by heavy metals during the process of discharging waste.

Structure

Thanks to the machine’s D-shapedvat, the way of generating vortex in the conventional pulper has been changed.The vortex is intensified so that the paper bale can be quickly soaked into theliquid. In thisway, the pulping time is decreased and the production capability of the pulpingmachine can be improved.

Specifications of

| Model | Capacity(t/24h) | Effective volume(m3) | Rotor diameter(mm) | Rotor type | Stock consistency(%) | Screen hole size(mm) | Motor power(KW) |

| ZDS80 | 60~70 | 10 | Ф850 | P.S.Vokes | 3~5 | Ф10~24 | 132 |

| ZDS81 | 100~120 | 15 | Ф1000 | 3~5 | Ф10~24 | 160 | |

| ZDS82 | 130~170 | 20 | Ф1150 | 3~5 | Ф10~24 | 200 | |

| ZDS83 | 180~220 | 25 | Ф1300 | 3~5 | Ф10~24 | 250 | |

| ZDS84 | 230~270 | 30 | Ф1500 | 3~5 | Ф10~24 | 280 | |

| ZDS | 270~300 | 35 | Ф1700 | 3~5 | Ф10~24 | 315 | |

| ZDS85 | 300~350 | 40 | Ф1700 | 3~5 | Ф10~24 | 355 | |

| ZDS86 | 360~420 | 50 | Ф1950 |